The media andia filter panels offered by Filtrotecnica Italiana are available in two main types:

– lofted non–woven blend of synthetic fibres of different lenght and diameter bonded with special bond;

– Continuous strands of glass fibres of different diameter graduated in density from front to rear and joined together with a plastic bond.The next table summarizes the different types and the pertinent technical data. All the listed materials can be supplied in rolls, pads or retained in rigid frames as filter panels.

Using the above mentioned media in a plat or pleated way it is possible to obtain a series of filter panels. These panels are normally made with a rigid galv. steel frame and front and rear galv. steel nets. It is possible a partial cleaning of these panels through a proper washing procedure. The frame in the fiber glass flat panels is completely made in die–cutted cardboard therefore the cleaning is impossible and after the use must be thrown away.

For heavy application as: coarse prefiltration, oil mist separation, industrial ventilation, mobile equipments filtration on exhaust kitchen hoods Filtrotecnica Italiana proposes a series of completely metallic panels as per table below. To increase the dust holding capacity and the final arrestance these filters must be impregnated with a special adhesive oil. It is possible the complete regeneration of these panels by means of suitable washing and if it is necessary a re – oiling. The above filter panels can be installed in flat position, normally perpendicular to the air direction, into special U slides that allow on easy extraction for maintenance. In case it is required a better tight between panels and holder the use of counter frames normally in galv. steel or st.st., as mentioned below, is suggested.

Counter frame CT

To install the above filter panels, bag filters or flanged filters a serie of counter frames made in galv. steel or st.st. AISI 304 complete with springs and neoprene seal gasket are available. To treat high air volume any number of counter frames can be bolted together to suit the required installation. The special bolts are normally supplied while the eventual stiffening profiles, if necessary, must be added.

Bag Filters and Filter Panels

Media and filter panels

Bag Filters

The bag filters have been designed to be employed wherever a high filtering efficiency and a long service life are required. Thanks to the large filtering area, included into reduced outline dimension, and to the high technology of the material employed, these filters are particularly suitable for air conditioning plants of offices, computers rooms, hospitals, pharmaceutical and food industries, pre filter of absolute filter for clean rooms etc. Bag filters consist of a series of single bags mounted on a rigid extruded aluminium frame, at perfect seal. In the FTB series the filter media is composed by ultra–fine glass fibres supported in the air leaving side by a nylon backing material to insure filter media integrity. In the FTA series the filter media is no woven synthetic with two layers and a nylon backing material to increase the stability. Filtrotecnica produces in addition also the FTS series with a synthetic lofted media, mainly suggested for applications as pre-filter.

FTV Filters – Glass fibers media

They are available in the efficiencies shown below and established by the UNI EN 779 dust spot method with atmospheric dust. The dust spot test will be replaced with the new test EN 779-2002 referred to particles of 0,4 µm that give values equivalent to the dust spot method. The suggested final pressure drop is 450 Pa.FTA Filters – Synthetic media

Same construction as glass fibres series but with filtering media in synthetic fibres. Design dimensions and technical data as FTV series. Available in the efficiencies shown below and established by the EN 779 dust spot method or EN 779-2002 on 0,4 µm. Suggested final pressure drop 450 Pa.FTS Filters – Synthetic lofted media

FTS bag filters are for applications where a high coarse build-up capacity rather than a high filtration efficiency is required with a low pressure drop. Typical application is the use as pre-filter on high efficiency filtering systems in dusty areas. The filter consists of a series of self supporting pockets in three standard depths made of loft synthetic media with a rigid galv. steel frame with a perfect tightness. The filtration arrestance is 87% according to EN 779 (class G3). Suggested final pressure drop 250 ÷ 300 Pa.

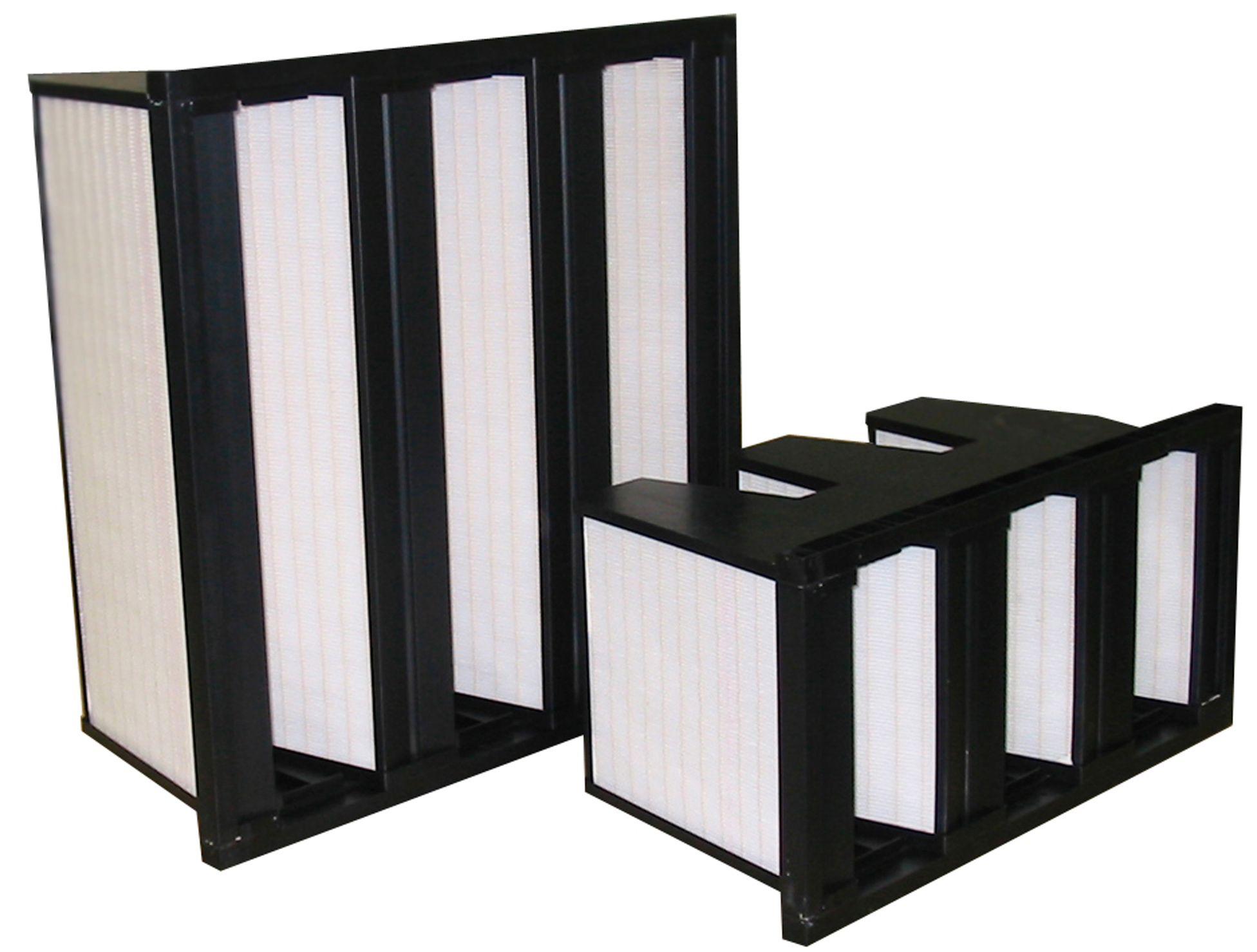

Rigid pockets filters

Minipleat rigid pockets filters FTR made with glass fibres paper insert in three degree of efficiency: 65% (class F6), 85% (class F7), 95% (class F9) according to Norm UNI EN 779 dust spot or EN 779-2002 on 0,4 µm. particles. Mainly used as pre–filters ahead of HEPA filters to increase the service life of the letter or as final filters in air conditioning and ventilating systems when high volume flows and extended filter service life are required. Their rigid, self–supporting structure allow high final pressure drop without risk of burst.

Construction materials

Frame: polystyrene fully incinerable or galv. steel (max temp. 120° C).

Filter media: glass microfibres paper folded into closely spaced pleats with thermoplastic spacers.

Sealant: polyurethane cold poured.